Without it, fishermen cannot embark on any fishing expedition. It’s perhaps the most important tool for the catch. Usually described as the fisherman’s number one companion, canoes or fishing boats are crafted through rigorous processes before gliding into the sea or any other water body to catch the fish that spices your favourite meal.

In this feature, I explore the business of canoe building and tell the story of the boat maker.

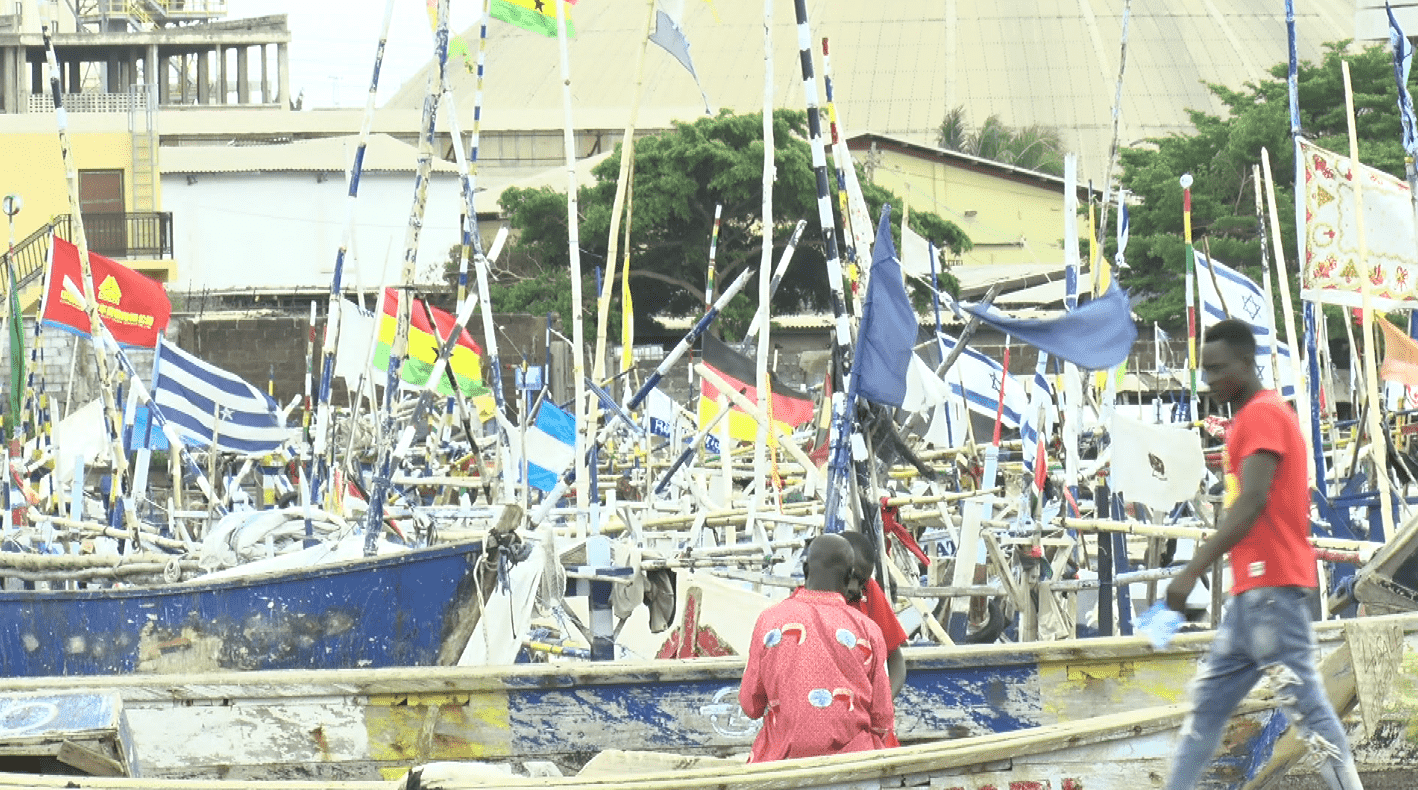

Sights and scenes from the Tema fishing harbour. It is early morning. I am here not to get the first catch for myself or even buy to resell. Rather, how fishing boats or canoes are made is what has brought me here.

Sounds of saws, and hammers and the scent of fresh wood are what greet me. Many canoes are in sight. Different in size and shape with a number of them at various stages of construction. I meet a man in his forties, leading one of the carving processes.

He tells me all begins with the search for the right wood that will ensure the strength, durability and balance of the canoe.

“I have a canoe, but it’s no longer fit for use, and I am unable to repair it due to the difficulty of obtaining wood for a new base. Typically, we coordinate with suppliers in the hinterlands who negotiate with local chiefs to procure the wood for us. Not just any wood will do; ‘Wawa’ is the preferred choice because of its ability to float on the sea”, Philip Adjei narrates.

Richard Quaye has also been in the business of canoe-making for about a decade. He is a full-time carver, with about 20 young men under him as apprentices. The high cost of a new canoe has forced him and his boys to fall on abandoned canoes to fix them into new ones.

Six years ago, all he needed was about GHS 17,000 to order the wood, but today, it’s running into hundreds of cedis. This does not even include the cost of the outboard motor.

“The prices are high now if you want to build a canoe from scratch. What we do instead is salvage abandoned canoes that are wasting away. This helps us save costs. We repair and patch them with other materials to create a well-designed canoe because we can no longer afford the astronomical prices.”

Because of this, the search for wood is taking carvers to the Ivory Coast, albeit at outrageous prices. In addition, carvers are paying GHS 2,500 for transportation. The same amount is spent to finish the paperwork to get the wood.

“Due to the government’s directive against the felling of trees, logs no longer come from our usual forest areas in the country. As a result, wood suppliers are now going into the forests of Ivory Coast to cut wood for canoes, which is contributing to the increase in prices”.

Once the wood is selected, it’s time to start shaping the base of the canoe, which is the hull. Large logs are transported here and are cut into planks. This is where craftsmanship comes to bear.

Each plank is shaped and bent to form the curved sides of the canoe, a process that requires artistic skill, precision, and experience. Every wood, every joint, and every nail matters.

“The log is split into two halves to create the base of the canoe. The pieces are then bent and nailed one after the other onto the hull to give the canoe its shape and form. Cross-linear wooden ribs are added at intervals to reinforce the base. This process involves a series of chiselling, stitching, and bending of various parts”, one of the carvers told me.

It takes about one to three weeks for these carvers to make a canoe from scratch. This is dependent on the size and the level of manual labour involved. Every canoe tells a story. From the hands that shaped it to the belief of the owner.

Once the hull is complete, the boat is caulked. It’s then sanded, patterned, and painted with each layer, adding protection against the harsh sea conditions.

“We handle the furnishing ourselves. We have team members who design the patterns and others who assist with the painting to achieve the desired aesthetic value. For example, one inscription means ‘don’t touch it.’’ It means that only those who worked for the harvest have the right to benefit from it. The inscriptions are based on individual philosophies, and people choose them for various reasons”, Richard adds.

The canoe maker, the canoe owner, and the fisherman are inseparable business partners. They form an unbreakable bond, as is evident in how the spoils are shared after a successful harvest.

Richard disclosed that “canoe owners usually have a good relationship with the fishermen. Profits are shared after deducting the cost of fuel from the proceeds. The remainder is then distributed between the owner and the fishermen. It’s important to avoid disagreements over money, as they can have numerous negative consequences on our operations.”

Canoes provide a means for fishing. But it’s not just about making them; it’s about building a lifeline for fishermen, and it’s a craft that transcends tradition and generations. Like any other craft, there are cultural dos and don’ts.

“Our occupation abhors immoral behaviours, so we avoid acts that could jeopardize our livelihoods. For example, one cannot approach the canoe immediately after a sexual encounter. It is believed that doing so negatively affects the quantity of our catch.”

After all the processes are concluded, it’s there that the religious leader of the owner is called to perform the necessary rites before the canoe enters the sea.

Even with the modernisation of fishing, dugout canoes typically made from a single tree trunk are predominantly used for artisanal fishing along the coastal communities of Ghana. In these areas, it’s a means of survival for most families.

Sitting on the stern of one of the nicely made canoes. I wondered. Owning one could cost a fortune. But what options do these carvers have? They definitely have to keep their businesses afloat.

![[FREE FREE MONEY] Predict and Win a Guaranteed GH¢200 From Us EVERY WEEK](https://wordpress.ghanatalksradio.com/wp-content/uploads/2022/02/Predict-and-Win-Final-09-03-2021-218x150.jpg)

![[Predict & Win – 8th/Oct.] WIN A Guaranteed ¢200 From Us This Week](https://wordpress.ghanatalksradio.com/wp-content/uploads/2021/10/maxresdefault-16-218x150.jpg)

![[Predict & Win – 2nd] WIN A Guaranteed ¢200 From Us This Week](https://wordpress.ghanatalksradio.com/wp-content/uploads/2021/09/maxresdefault-50-218x150.jpg)

![[Predict & Win – 25th] WIN A Guaranteed ¢200 From Us This Week](https://wordpress.ghanatalksradio.com/wp-content/uploads/2021/09/maxresdefault-36-218x150.jpg)

![[Predict & Win – 18th] WIN A Guaranteed ¢200 From Us This Week](https://wordpress.ghanatalksradio.com/wp-content/uploads/2021/09/maxresdefault-23-218x150.jpg)

![[National cathedral] See full list of churches that have contributed since 2018](https://wordpress.ghanatalksradio.com/wp-content/uploads/2020/09/Ghana-National-Cathedral-GhanaTalksRadio-100x70.jpg)